簡介:

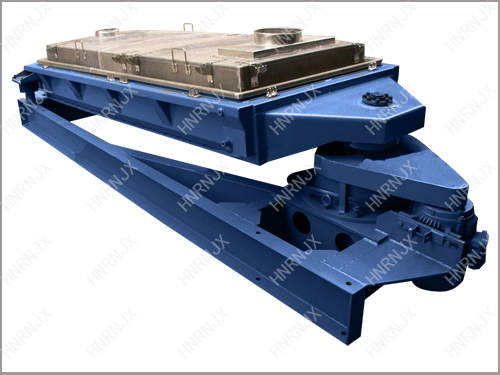

**精(jing)密(mi)平(ping)面(mian)回轉篩,它包(bao)括有一個機(ji)(ji)座4和一個篩面(mian)上(shang)(shang)安裝(zhuang)有彈性球的篩體(ti)(ti)(ti)2,機(ji)(ji)座的兩(liang)端(duan)(duan)外側分別設有一個龍(long)門(men)吊(diao)架(jia)1,在(zai)(zai)兩(liang)個龍(long)門(men)吊(diao)架(jia)與機(ji)(ji)座的掛環上(shang)(shang)分別連(lian)接(jie)有將機(ji)(ji)座水(shui)平(ping)吊(diao)起的吊(diao)繩3,在(zai)(zai)機(ji)(ji)座上(shang)(shang)面(mian)靠一端(duan)(duan)安裝(zhuang)有一套驅(qu)動(dong)(dong)裝(zhuang)置(zhi)5,在(zai)(zai)驅(qu)動(dong)(dong)裝(zhuang)置(zhi)上(shang)(shang)面(mian)安裝(zhuang)有傳動(dong)(dong)箱6,在(zai)(zai)傳動(dong)(dong)箱上(shang)(shang)經主(zhu)動(dong)(dong)軸、從動(dong)(dong)軸及(ji)其偏心塊與篩體(ti)(ti)(ti)的加料口一端(duan)(duan)相連(lian)接(jie),篩體(ti)(ti)(ti)的另(ling)一端(duan)(duan)向下(xia)傾斜3-8度(du)用吊(diao)繩吊(diao)掛在(zai)(zai)另(ling)一端(duan)(duan)的龍(long)門(men)吊(diao)架(jia)上(shang)(shang)。

**精(jing)密平(ping)(ping)面(mian)(mian)回轉(zhuan)(zhuan)(zhuan)篩(shai)具有(you)設(she)(she)計合理(li)(li),結構簡單,運(yun)行平(ping)(ping)穩,全封閉結構,無塵染(ran),防(fang)堵孔,防(fang)粘網(wang)等(deng)優點。特(te)別(bie)是對吸濕(shi)性強、粘性大、易(yi)堵孔和粘網(wang)的(de)(de)(de)尿素篩(shai)分(fen)(fen)(fen)更為明顯(xian)。由(you)于(yu)采用(yong)了(le)平(ping)(ping)面(mian)(mian)回轉(zhuan)(zhuan)(zhuan)運(yun)動(dong)(dong)(dong)原理(li)(li),有(you)效(xiao)的(de)(de)(de)降低了(le)設(she)(she)備的(de)(de)(de)動(dong)(dong)(dong)靜比和基(ji)礎動(dong)(dong)(dong)載荷。該設(she)(she)備采用(yong)平(ping)(ping)面(mian)(mian)回轉(zhuan)(zhuan)(zhuan)振動(dong)(dong)(dong)篩(shai)上下(xia)(xia)振動(dong)(dong)(dong),網(wang)下(xia)(xia)有(you)自動(dong)(dong)(dong)清理(li)(li)設(she)(she)備,較傳統的(de)(de)(de)直(zhi)線篩(shai)而言,提高(gao)(gao)了(le)絲網(wang)壽命,噪音小,篩(shai)分(fen)(fen)(fen)面(mian)(mian)積大,將效(xiao)率(lv)(lv)由(you)原來的(de)(de)(de)93~95提高(gao)(gao)到了(le)99,推廣前景好。pxzs型(xing)平(ping)(ping)面(mian)(mian)回轉(zhuan)(zhuan)(zhuan)尿素篩(shai)分(fen)(fen)(fen)機主要是針對大顆(ke)尿素的(de)(de)(de)篩(shai)分(fen)(fen)(fen)開(kai)發的(de)(de)(de)一(yi)(yi)種(zhong)新(xin)(xin)型(xing)篩(shai)分(fen)(fen)(fen)設(she)(she)備,也廣泛(fan)應用(yong)于(yu)冶金、礦(kuang)山(shan)、化(hua)工(gong)、醫藥、建材、糧食加工(gong)、耐火材料等(deng)行業的(de)(de)(de)精(jing)確分(fen)(fen)(fen)級篩(shai)分(fen)(fen)(fen)作業。是一(yi)(yi)種(zhong)新(xin)(xin)型(xing)的(de)(de)(de)高(gao)(gao)標準(zhun)篩(shai)分(fen)(fen)(fen)設(she)(she)備,該系列設(she)(she)備具有(you)篩(shai)分(fen)(fen)(fen)效(xiao)率(lv)(lv)高(gao)(gao),篩(shai)網(wang)利用(yong)率(lv)(lv)高(gao)(gao),工(gong)作穩定可(ke)靠,不易(yi)將合格(ge)的(de)(de)(de)顆(ke)粒振碎,無污(wu)染(ran),是一(yi)(yi)種(zhong)理(li)(li)想(xiang)的(de)(de)(de)環(huan)保型(xing)篩(shai)分(fen)(fen)(fen)設(she)(she)備。

(1)自清(qing)網效果*佳(jia),每層篩網均設有篩網防堵清(qing)理裝置(zhi),不堵網;

(2)處(chu)理量(liang)大,降低了成品(pin)物料中的粉末(mo)含量(liang),是普通(tong)篩(shai)子的10倍;

(3)篩(shai)網利用率(lv)高(gao),無垂直(zhi)振動,壽命長;

(4)全封(feng)閉(bi)結構無(wu)粉塵污(wu)染,改(gai)善操作員(yuan)的工作環(huan)境(jing)。

適用行(xing)業(ye):

(1)化工:化肥(fei)、純堿、鈣粉、樹(shu)脂(zhi)、三聚氰胺等;

(2)食品:砂糖、食鹽(yan)、淀粉(fen)、奶粉(fen)等;

(3)冶(ye)金:金屬、磁性材料等(deng);

(4)建材:涂(tu)料、耐火材料等。

工作原理:

從(cong)(cong)篩(shai)(shai)機搖動(dong)(dong)(dong)(dong)體(ti)即篩(shai)(shai)箱(xiang)運(yun)動(dong)(dong)(dong)(dong)軌跡來(lai)看,平(ping)面回旋篩(shai)(shai)又(you)稱往復(fu)篩(shai)(shai),其(qi)(qi)驅動(dong)(dong)(dong)(dong)裝(zhuang)置(zhi)所(suo)產生的(de)振動(dong)(dong)(dong)(dong)力(li)(li)(li)是一(yi)(yi)(yi)繞(rao)定(ding)軸(zhou)、方向(xiang)呈(cheng)一(yi)(yi)(yi)定(ding)規律變化的(de)慣(guan)性力(li)(li)(li),其(qi)(qi)本質是由偏心輪繞(rao)定(ding)軸(zhou)轉動(dong)(dong)(dong)(dong)所(suo)形成的(de)往復(fu)慣(guan)性力(li)(li)(li)。根據回旋篩(shai)(shai)的(de)結構特點及工作(zuo)原理,其(qi)(qi)篩(shai)(shai)面一(yi)(yi)(yi)般(ban)為(wei)水(shui)平(ping)或微傾(qing)斜布置(zhi)。回旋篩(shai)(shai)的(de)工作(zuo)原理為(wei):篩(shai)(shai)機啟動(dong)(dong)(dong)(dong)后(hou),篩(shai)(shai)機搖動(dong)(dong)(dong)(dong)體(ti)即篩(shai)(shai)箱(xiang)在慣(guan)性力(li)(li)(li)的(de)作(zuo)用下(xia)作(zuo)前后(hou)往復(fu)運(yun)動(dong)(dong)(dong)(dong),篩(shai)(shai)箱(xiang)帶動(dong)(dong)(dong)(dong)篩(shai)(shai)面作(zuo)周(zhou)期(qi)性搖動(dong)(dong)(dong)(dong),從(cong)(cong)而使篩(shai)(shai)面上的(de)物(wu)料(liao)隨篩(shai)(shai)箱(xiang)一(yi)(yi)(yi)同作(zuo)定(ding)向(xiang)跳躍(yue)式運(yun)動(dong)(dong)(dong)(dong),期(qi)間,小于篩(shai)(shai)面孔徑的(de)物(wu)理通(tong)過篩(shai)(shai)孔落到下(xia)層,成為(wei)篩(shai)(shai)下(xia)物(wu),大于篩(shai)(shai)面孔徑的(de)物(wu)料(liao)經連(lian)續翻(fan)滾(gun)跳躍(yue)運(yun)動(dong)(dong)(dong)(dong)后(hou)從(cong)(cong)排(pai)料(liao)口(kou)排(pai)出(chu),**終完成篩(shai)(shai)分(fen)工作(zuo)。

從平面(mian)回轉(zhuan)篩(shai)(shai)的(de)(de)結構和(he)(he)工作(zuo)(zuo)原理(li)可(ke)以(yi)看(kan)出,其傳動機構偏心輪距物料(liao)(liao)運動軌跡(ji)及物料(liao)(liao)在(zai)篩(shai)(shai)面(mian)上的(de)(de)滯留時(shi)間有(you)(you)至關重要的(de)(de)影響(xiang)(xiang),也(ye)即對(dui)篩(shai)(shai)機處(chu)理(li)能(neng)力和(he)(he)篩(shai)(shai)分效率(lv)有(you)(you)相反的(de)(de)影響(xiang)(xiang),有(you)(you)鑒于(yu)此,在(zai)實(shi)際篩(shai)(shai)分作(zuo)(zuo)業(ye)中,我們可(ke)以(yi)根據具體(ti)情況和(he)(he)需(xu)要,在(zai)生產(chan)能(neng)力和(he)(he)篩(shai)(shai)分效率(lv)兩(liang)方面(mian)有(you)(you)所取舍。

同樣或相近的(de)配置(zhi),平面回旋篩(shai)比(bi)一般慣性(xing)振動(dong)篩(shai)有(you)更高的(de)處理能力和(he)篩(shai)分效率,其本質(zhi)是(shi),該(gai)機(ji)型可(ke)人為的(de)控制物(wu)料在(zai)篩(shai)面上的(de)運動(dong)軌(gui)跡和(he)滯(zhi)留(liu)時間(jian),即在(zai)有(you)限(xian)空間(jian),由于物(wu)料的(de)運動(dong)軌(gui)跡為速度(du)和(he)加(jia)速度(du)均為變化非線(xian)性(xing)曲線(xian),所以,物(wu)料與篩(shai)面有(you)更多接觸機(ji)濾(lv),當然也就增加(jia)了透篩(shai)率。